D Fenders

D fenders are commonly used for marine applications to protect boats and other vessels from damage when they come into contact with docks or other structures. The curved shape of the fender helps to distribute the force of impact, reducing the risk of damage to the vessel.

D fenders are a type of rubber fender that are designed to absorb impact from ships and boats. They are named after their D-shaped cross-section, which allows them to be installed easily on the side or stern of a vessel. D fenders are typically made of high-quality rubber and are designed to withstand high levels of stress and impact.

D fenders come in a range of sizes, making them suitable for various sizes of vessels. They are commonly installed on smaller vessels, such as tugboats and fishing boats, as well as on larger commercial vessels, such as container ships and oil tankers.

The advantages of D fenders include their ease of installation, their ability to absorb large amounts of impact, and their durability. Additionally, they are relatively low-maintenance and can be easily replaced when necessary.

d rubber fender, boat d rubber fender, d rubber fender price, d rubber fender suppliers, d type rubber fender

Characteristics

► Simple and economical design

► Easy to install and maintain

► Highly durable rubber fender

► Popular D type extrusion

► Tough rubber bumper

► All sizes can be customized

► Can be supplied in grey or white colours

Applications

● Marinas

● Jetties

● Pontoon protection

● Inland waterways

● General purpose fendering

● Small & large seacraft protection

d rubber fender, boat d rubber fender, d rubber fender price, d rubber fender suppliers, d type rubber fender

Specifications

| Application: | Impact protection in a variety of marine applications |

| Product: | Marine D Fenders |

| Hardness (Shore A): | 72° |

| Material: | Natural Rubber / SBR |

| Colour: | Black / Non-Marking Grey / White |

Technical Data

| PROPERTIES | TEST STANDARD | VALUES |

| Compound | - | NR / SBR |

| Density (Specific Gravity) | DIN 53505 | 1200 kg/m3 |

| Tensile Strength | DIN 53504 | ≥16 MPa |

| Elongation at Break | DIN 53504 | ≥350% |

| Tear Resistance (23°C) | DIN 53507 | ≥80 N/cm |

| Abrasion Resistance | DIN 53516 | ≤100mm3 |

| Compression Set (24hrs @ 70°C) | DIN 53517 | ≤40% |

| Ozone Resistance (ppm 20% 72hrs @ 40°C) | ISO 143/1 | No cracking visible by eye |

| Change In Hardness | DIN 53504 | ≤5° |

| Change In Tensile Strength | DIN 53504 | ≥80% |

| Change In Elongation at Break | DIN 53504 | ≥80% |

| Minimum Temperature | - | -30°C |

| Maximum Temperature | - | +70°C |

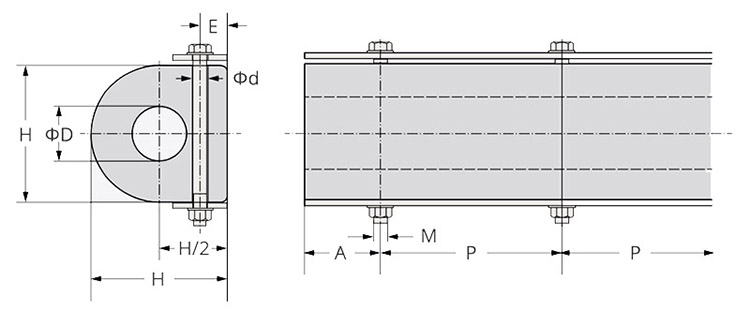

Dimensions

| Model | H | ØD | E | Ød | A | P | Flat Bar | M |

| HM-SD100H | 100 | 50 | 25 | 15 | 90~130 | 200~300 | 50x6 | M12 |

| HM-SD150H | 150 | 65 | 30 | 20 | 110~150 | 250~350 | 60x8 | M16 |

| HM-SD100H | 200 | 75 | 45 | 25 | 130~180 | 300~400 | 100x10 | M20 |

| HM-SD250H | 250 | 100 | 50 | 30 | 140~200 | 350~450 | 100x10 | M24 |

| HM-SD300H | 300 | 125 | 60 | 30 | 140~200 | 350~450 | 110x12 | M30 |

| HM-SD350H | 350 | 175 | 70 | 35 | 140~200 | 350~450 | 120x12 | M30 |

| HM-SD400H | 400 | 200 | 80 | 35 | 140~200 | 350~450 | 130x15 | M30 |

| HM-SD500H | 500 | 250 | 100 | 35 | 140~200 | 350~450 | 130x15 | M36 |

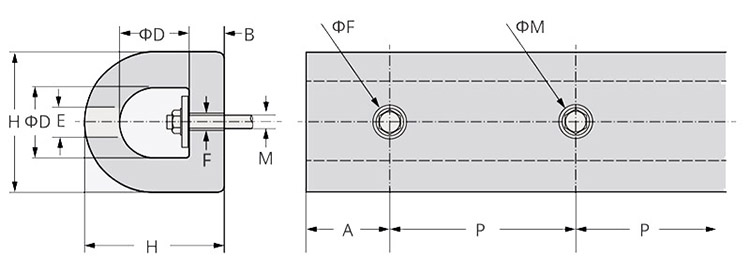

| Model | H | B | F | E | A | P | Flat Bar | M |

| HM-ZD100H | 100 | 25 | 24 | 30 | 90~130 | 200~300 | 40x5 | M12 |

| HM-ZD150H | 150 | 37.5 | 32 | 40 | 110~150 | 250~350 | 50x8 | M16 |

| HM-ZD200H | 200 | 50 | 40 | 50 | 130~180 | 300~400 | 70x10 | M20 |

| HM-ZD250H | 250 | 62.5 | 48 | 30 | 140~200 | 350~450 | 90x12 | M24 |

| HM-ZD300H | 300 | 72 | 48 | 30 | 140~200 | 350~450 | 100x12 | M30 |

| HM-ZD350H | 350 | 87.5 | 60 | 75 | 140~200 | 350~450 | 130x15 | M30 |

| HM-ZD400H | 400 | 100 | 60 | 75 | 140~200 | 350~450 | 150x15 | M30 |

| HM-ZD500H | 500 | 125 | 72 | 90 | 140~200 | 350~450 | 180x15 | M36 |

d rubber fender, boat d rubber fender, d rubber fender price, d rubber fender suppliers, d type rubber fender

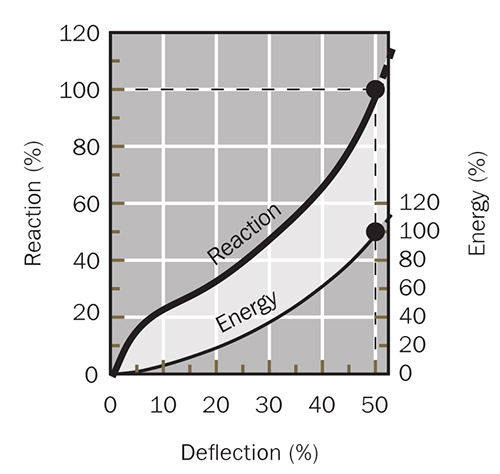

Generic Performance Curve

Detailed Photos

d rubber fender, boat d rubber fender, d rubber fender price, d rubber fender suppliers, d type rubber fender